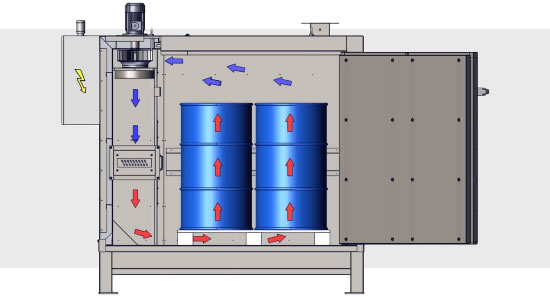

DRUM HEATING CABINETS

Thanks to over decades of experience in the continuous study of product and process, from large chemical plant to small workshops, by means of a standard solution or a completely customised solution, AMARC Drum Heating Cabinets are chosen for heating raw materials contained in drums or tanks. By pursuing the best thermal efficiency possibile and the highest level of functional safety.